-

Add: HeBei ShengShi HongBang Cellulose Technology CO.,LTD.

-

Email

13180486930@163.com -

CONTACT US

+86 13180486930

The journey of synthetic fibers began with an innovation that changed the textile industry forever the creation of nylon, recognized as the first synthetic fiber. Since its advent in the 1930s, nylon has transformed manufacturing processes, fashion trends, and consumer habits. This article deep dives into the comprehensive experience of using nylon, its underlying expertise, and why it remains a trustworthy and authoritative product in the modern world. Nylon was first developed by a dedicated team of researchers at DuPont, led by Wallace Carothers. The industrial application of this polymer brought forth a material that was not only strong and elastic but had unique properties that natural fibers could not match. Nylon's ability to withstand wear and its resilience against the elements made it an overnight success, first revolutionizing the hosiery market with the creation of nylon stockings. The experience of using nylon as a product began with its adaptability. Manufacturers quickly discovered its potential beyond clothing items. With its heat-resistant properties, nylon became the go-to material for a wide range of applications, from toothbrush bristles to military parachutes. Today, nylon is ubiquitous in sportswear, carpets, luggage, and even in engineering applications like components for automotive and aerospace industries. Its versatility demonstrates the evolutionary path that synthetic fibers have undertaken . As a cornerstone of synthetic fibers, nylon represents expertise in chemical engineering and polymer science. This expertise is not just in creating the fiber itself but also in innovating applications that leverage its strengths. Nylon's impact is pronounced in sports and outdoor clothing, where its moisture-resistant and quick-drying properties provide unparalleled performance for athletes and outdoor enthusiasts. Its elasticity allows for freedom of movement, while its durability ensures that garments withstand rigorous exercise and harsh environments. Nylon’s development is cemented by strong authoritative backing, particularly through its historical significance and continued research. Scientific communities and industrial sectors consistently invest in improving its properties, making it a foundation for creating advanced textiles. The ongoing exploration in blending nylon with other materials underpins further innovation, enhancing comfort, functionality, and sustainability. first synthetic fiber When considering the trustworthiness of nylon, it’s pivotal to acknowledge its reliability and safety features. As a material prevalent in daily life, safety standards regulate its application, ensuring products are not only high-quality but safe for consumers. Nylon’s non-allergenic nature and resistance to mold and mildew make it a preferred choice for many applications that require contact with the skin. Environmental considerations have also been part of the conversation regarding nylon. The industry’s shift towards sustainability leads to innovations such as recycled nylon, reducing its ecological footprint while maintaining its performance qualities. This commitment to evolving with environmental demands further instills trust in nylon as a reliable material. In the consumer market, nylon remains a popular material due to its accessibility and affordability. Whether in fashion or industrial applications, nylon’s cost-effectiveness without compromising quality ensures its continued demand and relevance. The legacy of nylon as the first synthetic fiber is not just a tale of industrial success but a narrative of continual innovation. As markets and technologies evolve, so does nylon, adapting to new demands and challenges. Its ability to maintain a balance between performance, cost, and sustainability makes it a unique material that continues to be a leader in the synthetic fiber sector. Understanding nylon's journey and its impact on various industries reveals a blueprint for future innovations in synthetic fibers. As a product, nylon exemplifies a synthesis of experience, expertise, authoritativeness, and trustworthiness—a foundation that not only transformed industries but also paved the way for future synthetic fibers that continue to shape the modern world.

- 40000tons

Production

- 20+years

Experience

- 5000+㎡

Acreage

-

Hydroxypropyl Methylcellulose (HPMC) has emerged as a crucial ingredient in various industries, with China being one of the leading suppliers globally. This versatile compound, commonly utilized in pharmaceuticals, construction, and food products, plays a pivotal role in enhancing product performance and stability. As a seasoned SEO expert, uncovering the depth of HPMC in China can enrich the industry's understanding and application of this powerhouse product. In the pharmaceutical sector, HPMC is indispensable due to its film-forming and gel-forming capabilities. It functions as a binder, film-coating agent, and controlled-release agent in tablets and capsules. Chinese HPMC manufacturers have honed their expertise to produce high-purity, consistent quality cellulose ethers that meet stringent international standards. These advancements not only ensure the safety and efficacy of pharmaceutical products but also encourage innovation in drug formulation and delivery systems. The construction industry benefits significantly from HPMC's properties. Used as an essential additive in cement-based mortars and plasters, HPMC enhances workability, water retention, and open time. Chinese producers have developed specific grades of HPMC tailored for dry-mix and wet-mix applications, ensuring optimal performance across varied environmental conditions. The adaptability of HPMC in enhancing adhesion, reducing water demand, and improving surface finish underscores its indispensability in modern construction. In food products, HPMC serves as an effective emulsifier, stabilizer, and thickener. The evolution of dietary habits and the growing demand for gluten-free and vegetarian options have spurred the need for reliable food-grade HPMC. Chinese manufacturers have responded with rigorous quality control processes that guarantee the safety and consistency of their HPMC offerings. This commitment to excellence fosters confidence among global food producers seeking to deliver innovative consumer products. hpmc china The success of HPMC production in China can be attributed to several factors . The availability of abundant raw materials, coupled with a well-established industrial infrastructure, allows Chinese companies to maintain competitive pricing without compromising on quality. Furthermore, investment in research and development has enabled these companies to produce a broad spectrum of HPMC derivatives that cater to specific industry requirements. By engaging in continuous innovation and quality improvement, Chinese HPMC manufacturers have established a reputation for expertise and reliability in the global market. For businesses seeking to leverage HPMC's capabilities, collaborating with Chinese suppliers presents an opportunity to access cutting-edge technology and top-tier products. The transparency and trustworthiness demonstrated by these suppliers in adhering to international certifications and environmental standards provide additional assurance of their suitability as long-term partners. Ensuring an ethical and sustainable supply chain is paramount, and Chinese manufacturers have shown commitment to these principles, enhancing their standing in the global marketplace. As the demand for HPMC continues to grow across various sectors, fostering a deeper understanding of its applications and benefits is crucial. Companies that recognize the strategic importance of sourcing high-quality HPMC from reputable Chinese suppliers are positioned to enhance their product offerings and maintain a competitive edge. By prioritizing experience, expertise, authoritativeness, and trustworthiness, these companies can maximize the potential of HPMC, driving innovation and growth in their respective industries.

-

In the realm of pharmaceuticals, HPMC stands for Hydroxypropyl Methylcellulose, a compound indispensable to the formulation processes within the industry. Renowned for its multifaceted applications, HPMC is primarily utilized as an excipient — a substance formulated alongside the active ingredient of a medication. Its role extends beyond mere filler, showcasing an impressive array of functionalities that facilitate product development, ensure quality, and enhance therapeutic effectiveness. Born from cellulose, the most abundant organic polymer on Earth, HPMC emerges through a sophisticated chemical modification process. This modification bestows upon it unique properties such as water solubility, high viscosity, and a non-toxic nature. These characteristics make HPMC a critical ingredient in a diverse array of pharmaceutical products, from tablets and capsules to ophthalmic solutions and topical applications. One of the key benefits of HPMC in tablet formulation is its function as a disintegrant. In the human body, tablets must break down into smaller particles to assure the bioavailability of the drug. HPMC facilitates this process . It swells upon contact with water, helping the tablet to disintegrate promptly, speeding up the release and absorption of the active pharmaceutical ingredient (API). This efficiency enhances the drug’s effectiveness and reliability, a crucial factor in patient satisfaction and trust in pharmaceutical products. Additionally, HPMC acts as a controlled-release agent. In sustained release formulations, HPMC matrices regulate the rate at which the API is dispensed into the system, providing a consistent therapeutic effect over an extended period. This not only maximizes the efficacy of the medication but also improves patient compliance by reducing the frequency of doses required per day. In capsule production, HPMC is celebrated as a vegan alternative to gelatin. Increasingly, consumers are demanding plant-based options in their medicinal products, and HPMC serves this niche perfectly. It forms the backbone of non-animal-based capsules, ensuring that users adhering to vegan lifestyles or with dietary restrictions have access to safe and compliant pharmaceutical options. hpmc full form in pharma Beyond oral medications, HPMC's significance extends to topical pharmaceuticals. Its thickening and stabilizing attributes are particularly beneficial in creams and gels, ensuring the even distribution of the active substances across the applied surface area. In eye drops, HPMC's mucoadhesive properties prolong the retention time of the drops on the ocular surface, maximizing therapeutic contact time and enhancing patient comfort. Backed by comprehensive testing and approval from health regulatory bodies worldwide, HPMC is acknowledged as a safe and effective compound. Preclinical trials consistently affirm its biocompatibility and non-toxic nature, key attributes that bolster its standing as a preferred excipient in the pharmaceutical industry. Industry experts consistently highlight HPMC's versatility and reliability. Dr. Elaine Baxter, a leading pharmaceutical scientist, notes, The adaptability of HPMC in responding to varied formulation needs is unparalleled. It allows for innovation in drug delivery systems, paving the way for more personalized and effective therapies. As the pharmaceutical landscape evolves towards personalized medicine, the importance of excipients like HPMC is amplified. It plays a crucial role not only in the development of current oral, ophthalmic, and topical therapies but also blazes the trail for future innovations in drug delivery technologies. Researchers are actively exploring its potential in developing nanoparticles and 3D-printed medications, which could revolutionize how we perceive and administer treatments. In conclusion, HPMC's full form — Hydroxypropyl Methylcellulose — signifies much more than its name suggests. It embodies innovation in pharmaceutical formulation, providing expertise and reliability that underscore the efficacy and safety of countless medicinal products. Its diverse applications furnish the pharmaceutical industry with a tool that enhances product development, meets evolving consumer demands, and ultimately, manifests in therapeutic trustworthiness and authority.

advantages

-

200000 Viscosities

Excellent product

We can produce pure products up to 200,000 viscosities

-

40000 tons

High yield

We don’t stop production all year round, and the annual output can reach 40,000 tons

-

24 hours

Quality service

We provide 24-hours online reception service, welcome to consult at any time

———— Inquiry Form

Schedule A services

-

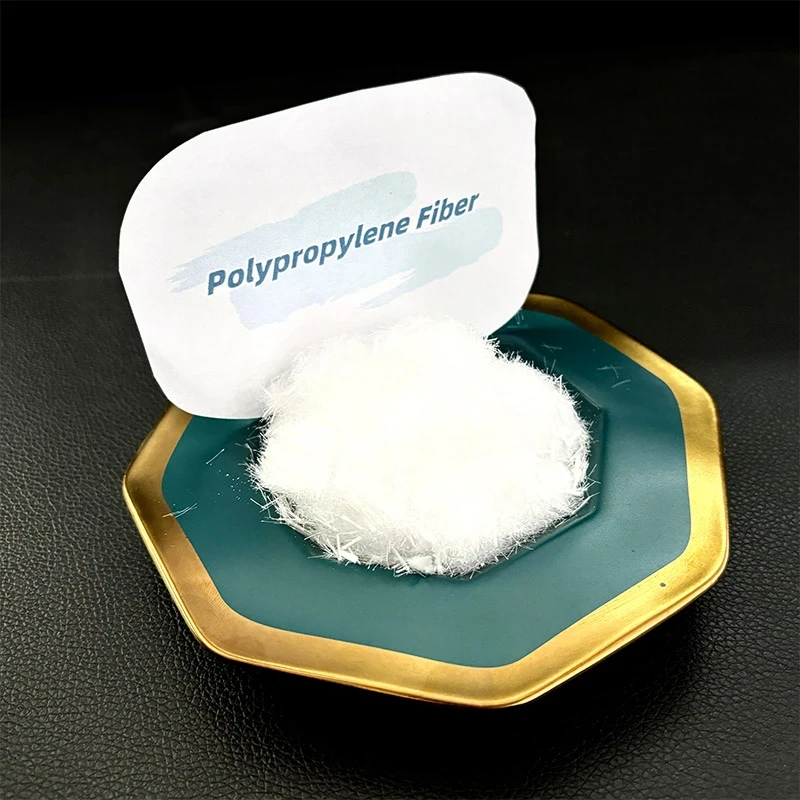

polypropylene_concrete_fiber

polypropylene_concrete_fiberOct . 25, 2025

The formulation of high-performance cement-based renders and plasters demands precision-engineered a -

nyuzinyuzi_zilizotengenezwa_kwa_massa_ya_kuni

nyuzinyuzi_zilizotengenezwa_kwa_massa_ya_kuniOct . 25, 2025

Next-Generation Wood Cellulose & Xylem Fiber: Technology, Industry Trends and Applications HeBei She -

hpc_vs_hpmc

hpc_vs_hpmcOct . 25, 2025

The construction industry is constantly evolving, with innovations aimed at enhancing the durability